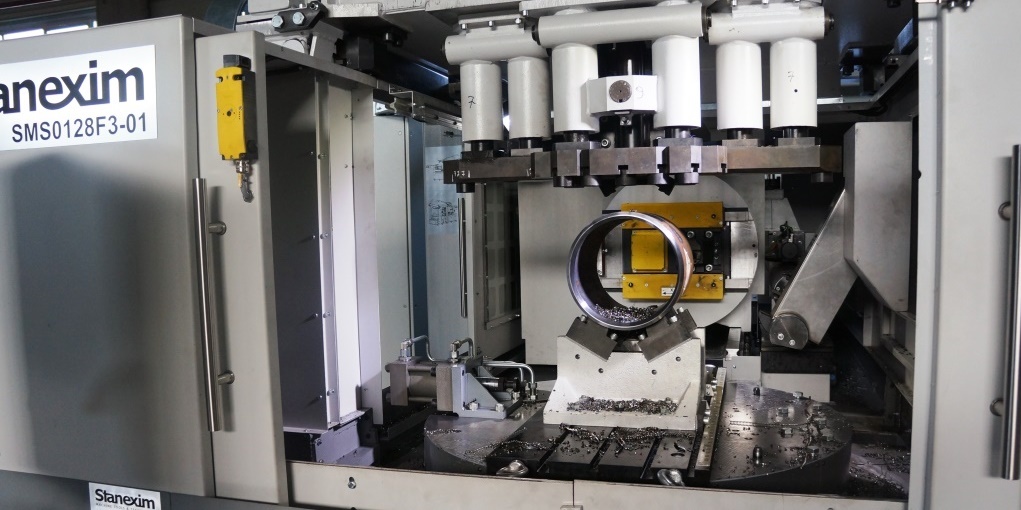

Processing of workpieces on the machine takes place in one set.The work piece is installed in changeable devices designed for basing and clamping workpieces during processing.

The billet measurement mechanism, which includes triangulation sensors and software developed by STANEXIM, allows to measure the actual pipe profile with high accuracy and make adjustments to the part processing program.

For workpieces clamping with different wall thicknesses, clamp pressure regulating is installed.

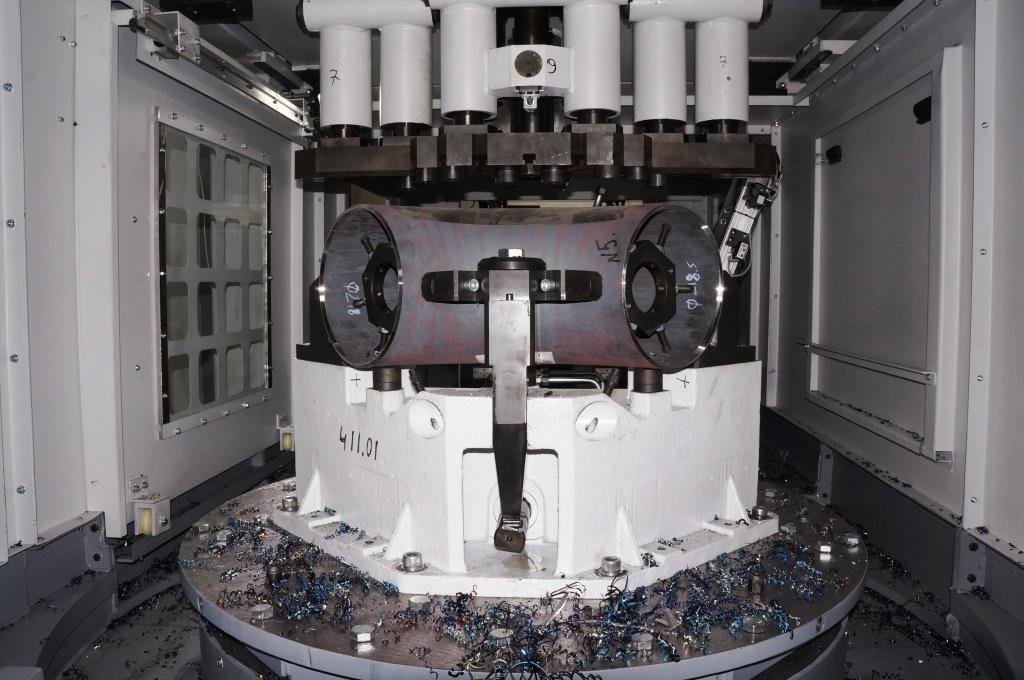

The rotary table provides processing of steeply bent bends with bending angles 30°, 45°, 60°, 90° and coils up to 630 mm long.

In August, the machine was successfully accepted and tested by the customer at the site in Minsk.

The machine fully complies with the customer's technical specification.

Read news about THE first SMS0127F3 machine