At the STANEXIM production site, a CNC machine is being manufactured for machining the ends of steeply curved bends.

The machine was designed by STANEXIM engineering department.

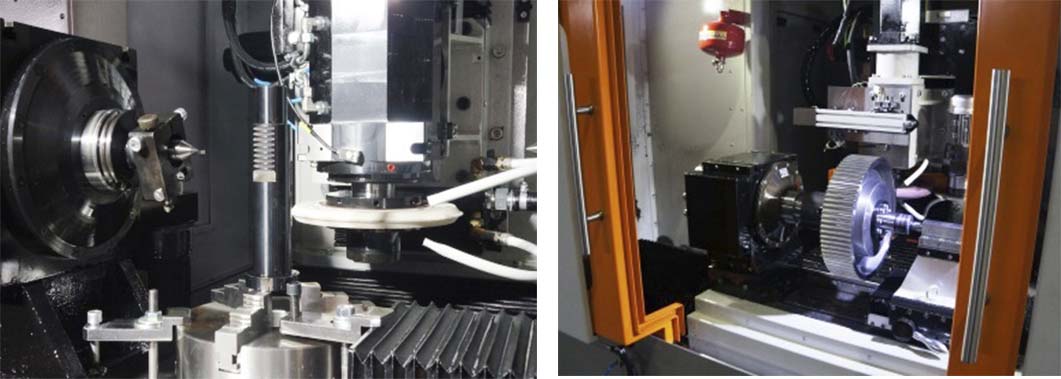

Some parts for a new machine are processed on gear grinding machine SMG405F2 that's also developed by STANEXIM.

SMG405 is designed for cam grinding of straight and oblique cylindrical gears, but it can process a wider range of parts.

Were produced:

- the driving wheel of boring head (material-steel 45, teeth number 80, diameter 354 mm). Grinding of the tooth profile for the gear belt RPP14 was performed;

- rail for the preload mechanism (module 2, toothed section of the rail length is 54 mm);

- a wide range of gears (module 1-10, teeth number 36-100, diameter up to 400 mm)The SMG405GF3 machine is equipped with proprietary software.

The SMG405GF3 machine is equipped with proprietary software. It allows to

- apply any profile specified by the program to the grinding wheel;

- to survey grinding wheel to the part automatically;

- perform correct cut distribution on the workpiece.